The Fourth Dimension, INC.

EXPERTISE

3d printing

3D printing or additive manufacturing is a process of making three dimensional objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created.

Vertical routing

The vertical routing/milling machine can create grooves of different profile, finish edges, create joints, drill with precision, make straight or shaped cuts, create mouldings and many other uses due to the many cutters that it can mount.

Bending Machine

A bending machine is a tool that shapes metal into different forms without cutting it. Bending machines are used in many industries, including aviation, shipbuilding, and metallurgy

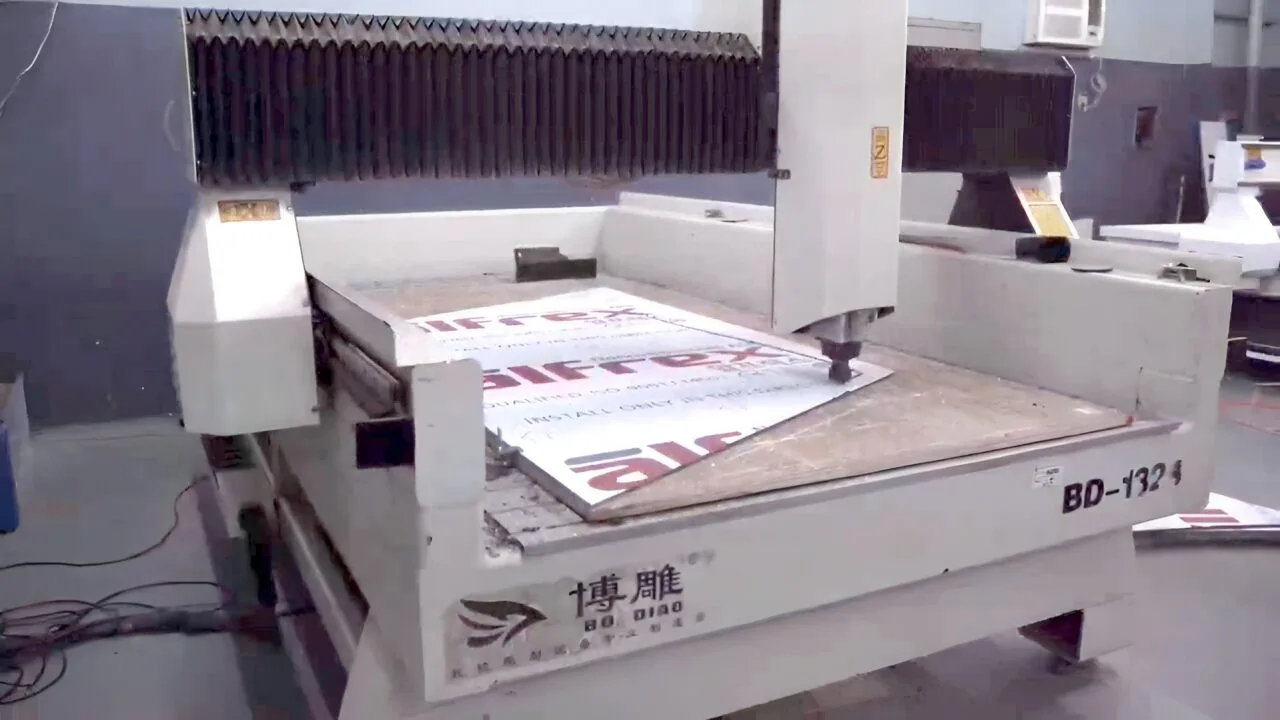

routing machine and engraving

A CNC routing machine, or computer numerical control router, is a machine that uses a computer to cut, carve, and engrave materials like wood, plastic, metal, and foam

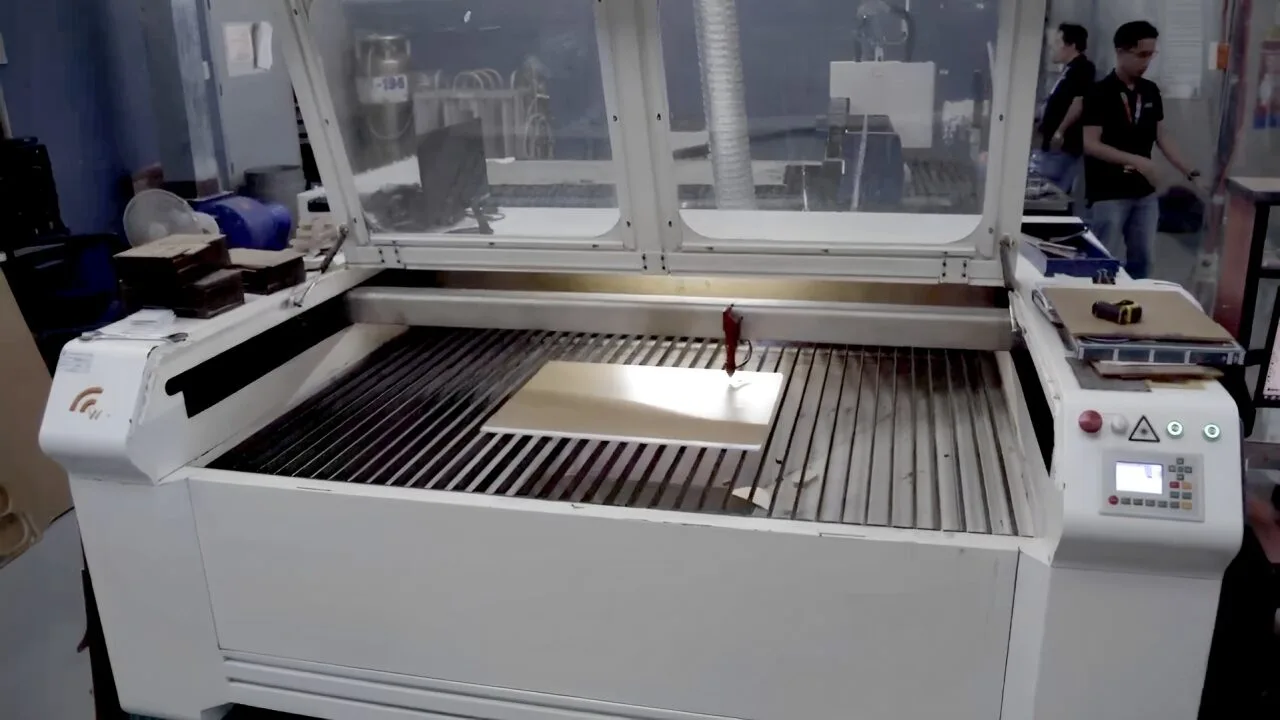

laser cutting machine

A CNC laser cutter is a piece of computer numerical control (CNC) equipment that uses a focused, high-powered laser beam to mark, cut, or engrave a material to form custom shapes

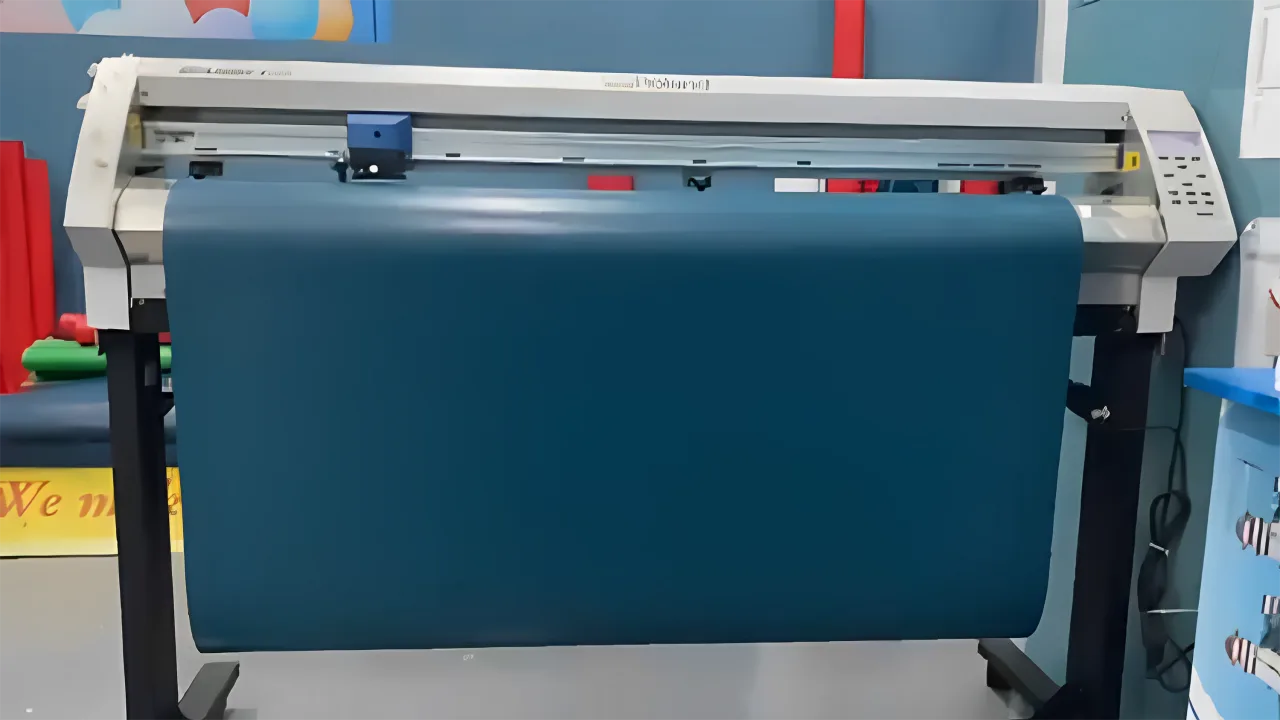

computer cut graphics

Computer cut graphics are images that are digitally cut to a precise shape and size using a computer-controlled blade

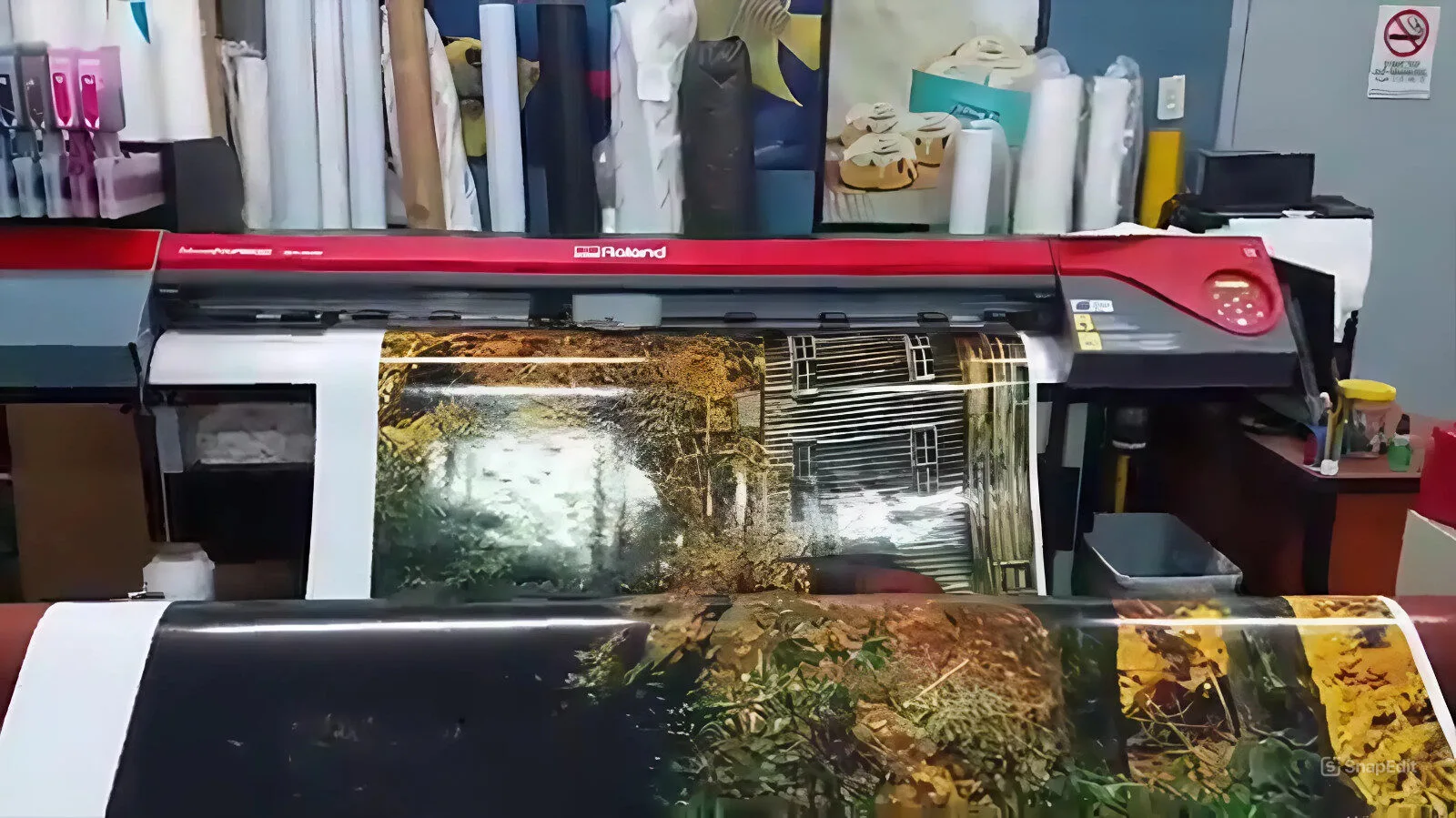

Large format printing

A large format printing machine, also known as a wide-format printer, is a computer-controlled machine that produces large-scale printed materials. These printers can print on a variety of materials, including paper, vinyl, metal, and fabric, and are used to create items like banners, posters, murals, and billboards.

Commercial Signs

Printing

Surfaces

When the company introduced the “internally-illuminated flexible-face sign” in the country in 1985, little did it realize the role it would play in the Philippine sign industry.

By May, 2015, the company would have tucked under its belt, 30 years of valuable experience in this field. Its knowledge, expertise and track record of reliable, on-time delivery and quality, is hard to beat in the country and equal, if not, surpass quality standards found in the western world.

Today, the company operates a completely automated facility for the production of architectural and commercial signs. No job is too big or too small for the company to handle, whether for interior or outdoor application, illuminated or non-illuminated, pole-mounted or wall mounted. Whether you need a sign to go on top of a building or a simple nameplate or number to go on the face of your door, the company is well equipped to address your need.

The company’s first biggest strength is the combined extensive experience of its design and production team. Our team can help you decide where and how best to position your sign to achieve maximum visibility. They can help you decide size, choose from a wide choice of sign materials and type of illumination best suited for your purposes.

The company’s other strength is capacity. With 5500sqm of covered space, automated, CAD-CAM cutting machines and large-format printing machines, it can deliver large-scale production output in very short periods of time. Its fleet of delivery and installation vehicles includes 10-wheeler, 40’ trucks with, mounted with 10T cranes and bucket lifts with up 25m reach, enough to handle most big jobs. It also employs enough manpower to handle installations nationwide.

Next time you have a requirement for whatever type sign or display, whether one or a hundred, for identity, for advertising, for interior or exterior, short term or long-term use, give us a call. Chances are, you will find everything you need under one roof.

The company’s introduction of full-color, large format printing in 1988, the second of only two machines in Asia at the time (the first one had arrived Hongkong 3 months earlier), would dramatically give life to what is now the vibrant outdoor advertising industry in the Philippines as we know it.

With a machine capable of printing a full-color, photographic image on any size, with a minimum order of one piece delivered in a couple of hours, the billboard industry was reborn.

Back in the day, billboards were just hand-painted metal sheets, which no one really paid attention to. With the introduction of full-color photographic images, billboards became a legitimate, important and serious advertising medium in the country. Large-format printing put the company in the global map of outdoor advertising.

While this product has become commoditized today, where a printer can be found in almost every street in the metropolis, the company still continues to print short run graphic displays for all types of applications – billboard and streamer tarps, fence barricade displays, murals, exhibit displays, bus and truck graphic displays, floor graphics, merchandising and point of purchase displays, as well as many others.

The company now has taken delivery of a new high throughput machine which features the latest technology in full color printing. It is a flat-bed printer, capable of printing on any rigid surface, including, but not limited to ceramic tiles, wood panels, fiber, foam and gypsum boards, using UHV inks.

Together with this new machine is an additional dye-sublimation printer that prints economically, water-proof, full-color images on synthetic paper – perfect for merchandising and POP’s.

One of the products that TFDI currently offers today is in the field of the “Finishing” aspects of the construction industry.

The company is the exclusive distributor of AVONITE brand solid surfaces used for all types of countertops and wall claddings, whether for interior or exterior.

Made by Aristech Acrylics in the USA, the material is classified as 100% acrylic, is available in solid and faux stone finishes, in thicknesses of 12mm, 6mm and 3mm, to cater to a wide range of applications and budget constraints.

AVONITE can be illuminated or non-illuminated. It is a preferred choice among those who are “in-the-know” in the finishing industry both here and around the world. It is well known for its proven performance against yellowing and discoloration, resistance to staining and fading, as well as its most important characteristic – anti-bacterial and anti-fungi properties.

If you are looking for a material that can clad countertops or any surface that will resist absorption of all liquids, staining, and bacteria, then you will find it in AVONITE.

The company has been fabricating this material for the last 4 years and has very extensive experience with this material. With the 3mm and 6mm thicknesses now available from Aristech, AVONITE can be used economically to clad shower enclosures, CR walls, restaurant and office furniture, selling area countertops, home kitchens and lavatories, basically anywhere where resistance to bacteria and liquids are desired characteristics.